A DIY DLP Resin 3-D printer

A DIY DLP Resin 3-D printer

One of the members of the Kansas City Hackerspace printed out his first object on his prototype DLP printer last night at the hackerspace. Very cool tech!

http://mike-ibioloid.blogspot.com/2012/ ... nting.html

http://mike-ibioloid.blogspot.com/2012/ ... nting.html

I uploaded some videos of the printer in action!

http://mike-ibioloid.blogspot.com/2012/ ... nting.html

http://mike-ibioloid.blogspot.com/2012/ ... nting.html

Maddyable, yes and yes. pick your favorite 3-d design program: Blender Inventor, google sketch up, Autodesk 123D. You just need to create a .stl file for most of the 3-d printing programs. Like ReplicatorG.

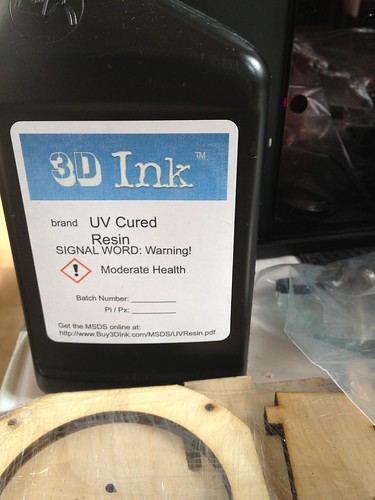

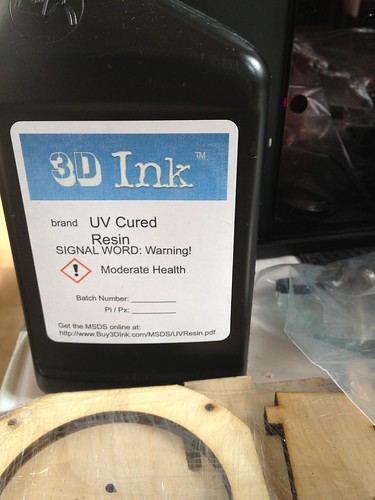

Limor, yes I know what is in the Resin but I am not sure I can tell you how to make it. One of the members of my local Hackerspace wants to start selling it through his company. I will post when he starts selling it

This will give you an idea of what is in it. He has his own version though.

http://3dprinter.wikidot.com/resin

Limor, yes I know what is in the Resin but I am not sure I can tell you how to make it. One of the members of my local Hackerspace wants to start selling it through his company. I will post when he starts selling it

This will give you an idea of what is in it. He has his own version though.

http://3dprinter.wikidot.com/resin

There are a surprising number of DIY 3D printer projects out there that have nothing to do with MakerBot or RepRap developments. The coolest one I’ve seen in months is Junior Veloso‘s DIY homemade high resolution 3D printer. Junior’s system builds the object upside down by projecting light from a DLP projector into a thin layer of UV resin. Each layer takes about 8 seconds to cure and the layers are about 0.1 mm thick.1 Between the high resolution from the DLP projector and the 0.1 mm vertical layer thickness, Junior is able to get some pretty incredible results as you can see above.

Junior's posts from 2010 are an inspiration to everyone but the latest interesting site/wiki that showed up the past days is Lemoncurry with some good information about the subject.

https://code.google.com/p/lemoncurry/wiki/main

https://code.google.com/p/lemoncurry/wiki/main

Hi Gort

Don't pay too much attention to herispitson's post as it seems a human spammer.

All his posts have the same structure: to state something obvious that's already been discussed or is well known and he then finishes the post with a sentence containing links to something completely unrelated (ie spam).

I've banned the user and edited his posts to remove the spam links.

I haven't removed the posts completely as they contain information that relates to the thread and kind of respect the posting rules.

In other news, the DLP printer project looks really, really cool.

I notice from the video you're using a very large projector. Is there any reason for this?

(I was wondering if the same effects could be achieved with a more compact Pico Projector but then I was left wondering how the video resolution and quality of the lens/focus affected the resolution of the printed part. )

Regards

Pedro.

Don't pay too much attention to herispitson's post as it seems a human spammer.

All his posts have the same structure: to state something obvious that's already been discussed or is well known and he then finishes the post with a sentence containing links to something completely unrelated (ie spam).

I've banned the user and edited his posts to remove the spam links.

I haven't removed the posts completely as they contain information that relates to the thread and kind of respect the posting rules.

In other news, the DLP printer project looks really, really cool.

I notice from the video you're using a very large projector. Is there any reason for this?

(I was wondering if the same effects could be achieved with a more compact Pico Projector but then I was left wondering how the video resolution and quality of the lens/focus affected the resolution of the printed part. )

Regards

Pedro.

Looks like Ron is almost ready for his kickstarter!

http://mike-ibioloid.blogspot.com/2013/ ... inter.html

http://mike-ibioloid.blogspot.com/2013/ ... inter.html

This looks very interesting.

Could someone outline the benefits of this tech. as opposed to

the current ABS printers?

I understand its been around longer and so on - I'm just wondering

if it has much advantage at this stage or if a lot more work is needed

to make it practical on a competative level?

How does it compare for speed, resolution and reliability for example?

Could someone outline the benefits of this tech. as opposed to

the current ABS printers?

I understand its been around longer and so on - I'm just wondering

if it has much advantage at this stage or if a lot more work is needed

to make it practical on a competative level?

How does it compare for speed, resolution and reliability for example?

If you need more information this is a good place to start.

http://3dprinter.wikidot.com/resin

Formlabs is now sending out it's version of a resin printer.

http://formlabs.com/

http://3dprinter.wikidot.com/resin

Formlabs is now sending out it's version of a resin printer.

http://formlabs.com/

Hi Gort

Thanks for the links.

I have seen both before but the Form1 site didnt have much info at all last time I looked. I was hoping for something a bit more hands on but perhaps I'm being premature there .

It seems things are going well for them which is nice.

The Form1 at $3,299 USD is very competative. A running cost comparison

would be nice at a later stage.

The specs they have posted seem comparable to the current devices with a better layer thickness:

Min. Feature

300 microns

(.012 inches)

Min. Layer Thickness

25 microns

(.001 inches)

Build Volume

125 x 125 x 165mm

(4.9 x 4.9 x 6.5 inches)

I havn't seen any figures for speed or post production durability

comparisons which I would like to see.

Would the finished material have the durability of ABS ? This could affect

who buys which maybe.

The printer above presumably is targeted at a similar specification to the form1?

They do seem to have a reasonably attractive device and have thought through the practicalities (the kit they supply is a good idea)

The biggest drawback that I can see is the disposal of the waste chemical.

Perhaps someone could do a 3D print of a big sealed container

Thanks for the links.

I have seen both before but the Form1 site didnt have much info at all last time I looked. I was hoping for something a bit more hands on but perhaps I'm being premature there .

It seems things are going well for them which is nice.

The Form1 at $3,299 USD is very competative. A running cost comparison

would be nice at a later stage.

The specs they have posted seem comparable to the current devices with a better layer thickness:

Min. Feature

300 microns

(.012 inches)

Min. Layer Thickness

25 microns

(.001 inches)

Build Volume

125 x 125 x 165mm

(4.9 x 4.9 x 6.5 inches)

I havn't seen any figures for speed or post production durability

comparisons which I would like to see.

Would the finished material have the durability of ABS ? This could affect

who buys which maybe.

The printer above presumably is targeted at a similar specification to the form1?

They do seem to have a reasonably attractive device and have thought through the practicalities (the kit they supply is a good idea)

The biggest drawback that I can see is the disposal of the waste chemical.

Perhaps someone could do a 3D print of a big sealed container

postscript: found it:

"How fast does the Form 1 print?

The build speed is comparable to other SL machines and varies depending on the complexity of your model. As a general rule, the build speed is 1.5 cm/hour along the Z axis. Our rook, for example takes around 2 hours."

note to self:

I must read the FAQ

I must read the FAQ

I must read the FAQ

I must read the FAQ

I must read the FAQ

I must read the FAQ...

"How fast does the Form 1 print?

The build speed is comparable to other SL machines and varies depending on the complexity of your model. As a general rule, the build speed is 1.5 cm/hour along the Z axis. Our rook, for example takes around 2 hours."

note to self:

I must read the FAQ

I must read the FAQ

I must read the FAQ

I must read the FAQ

I must read the FAQ

I must read the FAQ...

Hi mantrid

afaik the behaviour of the resin over time is currently the biggest "unkown" at the moment.

FFD machines (like the Replicator and similar) use standard, cheap, well known materials, including ABS and PLA.

There are new compounds being produced with PLA as it seems to work much better with FFD technology than ABS in terms of shrinkage and layer bonding (making strong parts).

Unlike what peolpe think, a part printed in a FFD machine in PLA is much stronger than its ABS counterpart. (this is matter for a separate thread which I hope I can post soon to clear this up).

Regarding the Form1 and all other UV based machines, they seem to be capable of impressive resolutions but no one yet knows in detail how each resin behaves (and how much it costs).

Different manufacturers seem to be using different combinatins or formulas.

When you inquire about a resin you can ask for the Materal Datashet and also for the MSD (Material Safety datasheet).

Here are a few things to look out for to compare materials:

From the Material datasheet (practical data, physical properties):

- Glass point

- Melting point

- Density (as it will affect how much each cubic centimeter costs to print).

- Resistance to UV

- Resistance to moist, water and/or rain

- Can the material be painted

From the MSD:

- Environmental precautions (ABS for examples can take 100-200 years to break down at a landfill)

- Potential health effects: eye contact, skin contact, ingestion, Inhalation (both uncured and cured).

- Flammability

Having said this, machines like the Form 1 have the great advantage of resolution over FFD machines.

FFD have other advantages such as the use of standard, fairly low cost materials (ABS, PLA) and possibility of tuning the printing speed vs resolution for fine printing or fast prototyping.

I'm sure there will be room for both technologies for some time to come and I don't even know if one will ever completely replace the other.

Regards

Pedro.

afaik the behaviour of the resin over time is currently the biggest "unkown" at the moment.

FFD machines (like the Replicator and similar) use standard, cheap, well known materials, including ABS and PLA.

There are new compounds being produced with PLA as it seems to work much better with FFD technology than ABS in terms of shrinkage and layer bonding (making strong parts).

Unlike what peolpe think, a part printed in a FFD machine in PLA is much stronger than its ABS counterpart. (this is matter for a separate thread which I hope I can post soon to clear this up).

Regarding the Form1 and all other UV based machines, they seem to be capable of impressive resolutions but no one yet knows in detail how each resin behaves (and how much it costs).

Different manufacturers seem to be using different combinatins or formulas.

When you inquire about a resin you can ask for the Materal Datashet and also for the MSD (Material Safety datasheet).

Here are a few things to look out for to compare materials:

From the Material datasheet (practical data, physical properties):

- Glass point

- Melting point

- Density (as it will affect how much each cubic centimeter costs to print).

- Resistance to UV

- Resistance to moist, water and/or rain

- Can the material be painted

From the MSD:

- Environmental precautions (ABS for examples can take 100-200 years to break down at a landfill)

- Potential health effects: eye contact, skin contact, ingestion, Inhalation (both uncured and cured).

- Flammability

Having said this, machines like the Form 1 have the great advantage of resolution over FFD machines.

FFD have other advantages such as the use of standard, fairly low cost materials (ABS, PLA) and possibility of tuning the printing speed vs resolution for fine printing or fast prototyping.

I'm sure there will be room for both technologies for some time to come and I don't even know if one will ever completely replace the other.

Regards

Pedro.