Automated 3d Scanner for David 3D Laserscanner

Automated 3d Scanner for David 3D Laserscanner

Hi everyone

Would like to share info on a small project i did here.

The David 3D Laserscanner is an affordable way to do 3d scans of objects, by moving a laser over the object placed in front of a calibration panel.

Each scan covers a face of the object, and the software then fuses all the scans in one 3d model.

However what is not widely know is that this process can be automated:

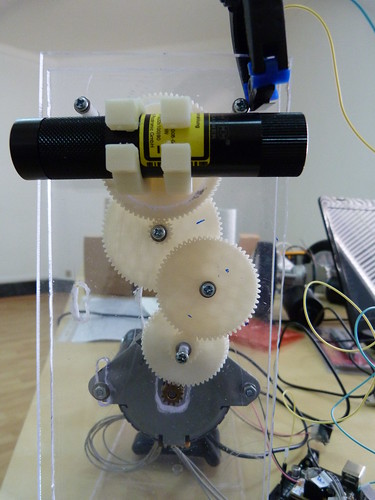

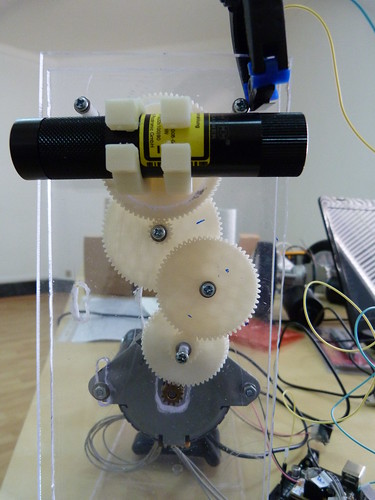

This hand made prototype consists of a stepper motor (salvaged from an old inkjet printer) and set of gears (created in our 3d printer that give it a gear ratio of over 100:1.

The stepper is controlled with an arduino, that in turn is controlled via David Laserscanner software trough serial port(over usb).

The end switch is used to calibrate the system after turning it on.

With this setup, plus an automated turn table, also controlled by the arduino, it is possible to completely automate the scanning process that usually takes a few minutes. The detail will also improve.

Another advantage is that this method also makes it possible to do the scans without the calibration panels. Albeit the calibration panels being needed for manual scanning they do sometimes cause unwanted reflections that create outliers in the models, that have to be removed my hand.

When we get our cnc up and running we might make a product out of this, to supply as an accessory to the kit.

Rgds

Would like to share info on a small project i did here.

The David 3D Laserscanner is an affordable way to do 3d scans of objects, by moving a laser over the object placed in front of a calibration panel.

Each scan covers a face of the object, and the software then fuses all the scans in one 3d model.

However what is not widely know is that this process can be automated:

This hand made prototype consists of a stepper motor (salvaged from an old inkjet printer) and set of gears (created in our 3d printer that give it a gear ratio of over 100:1.

The stepper is controlled with an arduino, that in turn is controlled via David Laserscanner software trough serial port(over usb).

The end switch is used to calibrate the system after turning it on.

With this setup, plus an automated turn table, also controlled by the arduino, it is possible to completely automate the scanning process that usually takes a few minutes. The detail will also improve.

Another advantage is that this method also makes it possible to do the scans without the calibration panels. Albeit the calibration panels being needed for manual scanning they do sometimes cause unwanted reflections that create outliers in the models, that have to be removed my hand.

When we get our cnc up and running we might make a product out of this, to supply as an accessory to the kit.

Rgds

For those that haven't seen this, the David Laser Scanner software is pretty nifty...

Similar systems can be found in industrial applications, though not requiring a reference surface - in industrial 2D laser systems, the line laser is fixed, as is the camera, thus via triangulation, depth can be determined: length of one side is known (from camera to laser on the device), and angle of camera (and subsequent location of beam detection) and angle of laser are known. In industrial 3D systems, this system (camera and laser) is simply moved over a surface in a controlled manner to create a composite 3D image.

Some 1D barcode scanners use a mirror with a magnet on a flexible strip controlled with a coil to move a single point laser back and forth to read a 1D barcode.

With this, I've been pondering the idea of a head-mounted camera and a line laser / magnetically actuated mirror for 3D scanning on a bot. As the angle of the mirror is slowly changed (and thus known via calibration) with the magnetic actuator, multiple scans could be used to generate a 3D image with the same method. One could use a servo to move the mirror as well, but electromagnetic would be more compact.

To note, this would only present one 3D "face" of an object, not an "all around" 3D such as mentioned above.

3D laser scanning on 'bots is right here at our doorstep!!!

Similar systems can be found in industrial applications, though not requiring a reference surface - in industrial 2D laser systems, the line laser is fixed, as is the camera, thus via triangulation, depth can be determined: length of one side is known (from camera to laser on the device), and angle of camera (and subsequent location of beam detection) and angle of laser are known. In industrial 3D systems, this system (camera and laser) is simply moved over a surface in a controlled manner to create a composite 3D image.

Some 1D barcode scanners use a mirror with a magnet on a flexible strip controlled with a coil to move a single point laser back and forth to read a 1D barcode.

With this, I've been pondering the idea of a head-mounted camera and a line laser / magnetically actuated mirror for 3D scanning on a bot. As the angle of the mirror is slowly changed (and thus known via calibration) with the magnetic actuator, multiple scans could be used to generate a 3D image with the same method. One could use a servo to move the mirror as well, but electromagnetic would be more compact.

To note, this would only present one 3D "face" of an object, not an "all around" 3D such as mentioned above.

3D laser scanning on 'bots is right here at our doorstep!!!

Just a quick update:

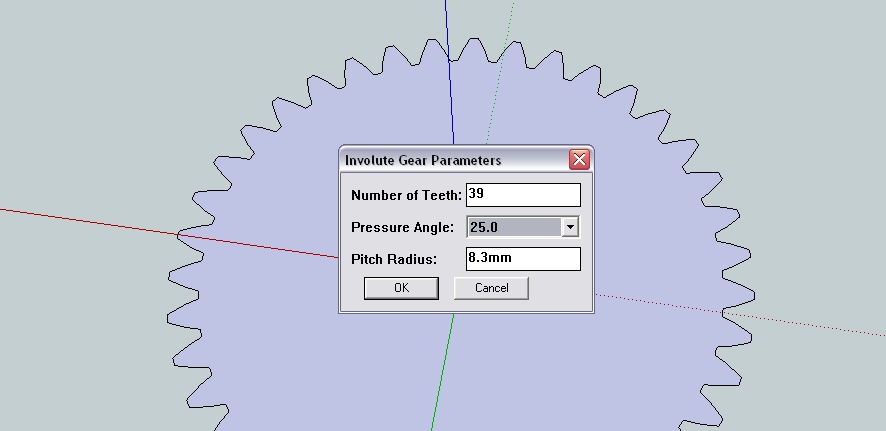

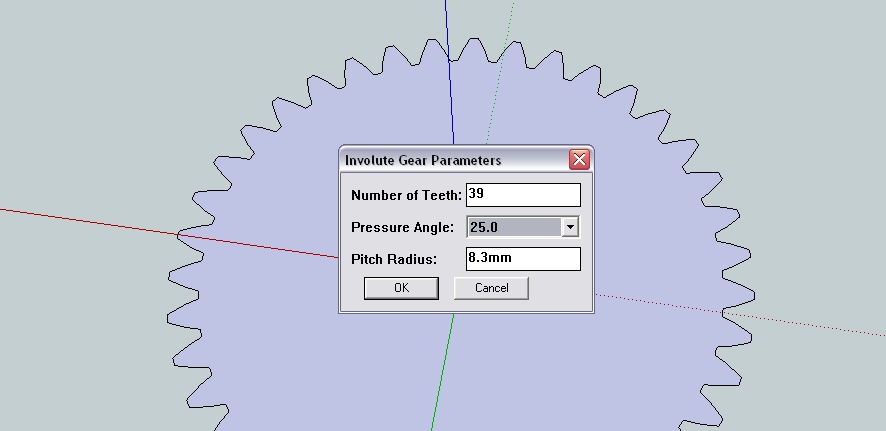

the gears were designed using a cool plug in for Sketchup that automatically draws them for you:

http://capolight.wordpress.com/2011/01/ ... -sketchup/

You just need to provide Radius, number of teeth and Pressure and the gears will be design for you:

Regards

Pedro.

the gears were designed using a cool plug in for Sketchup that automatically draws them for you:

http://capolight.wordpress.com/2011/01/ ... -sketchup/

You just need to provide Radius, number of teeth and Pressure and the gears will be design for you:

Regards

Pedro.

MarcoP wrote:Interesting idea

However magnetic is very non-linear so some position feedback would be required.

The results of these methods depend greatly on the accuracy of the laser angle.

Rgds

An electromagnetic actuator would be non-linear, but I should be able to soft-calibrate it by running a scan over a known-flat surface. I could use a PWM pin off my RB-100 to modulate the power to an electromagnet via MOSFET to alter deflection... A future "try me" thing to do, though.

I have a 2D "profile sensor" demo unit on my desk at work, BIG $$$. It's amazing how technologically simple these things are, but slap "industrial automation" on the label and they cost a fortune! I am curious to see what is possible with "consumer grade" hardware...

Re: Automated 3d Scanner for David 3D Laserscanner

i have never ued 3D barcode scanner, is there any different between the 1D barcode scanner and 2D barcode scanner. so when can i used it, can i use it on the normal barcodes,

Re: Automated 3d Scanner for David 3D Laserscanner

gdjump - haven't heard of a 3D barcode scanner, but 3D scanners (for scanning objects in 3 dimensions) wouldn't do too well with barcodes. 1D barcode scanners only require reading of the code in one dimension, a line. 2D barcode scanners require reading in 2 dimensions, ex, a picture.

Re: Automated 3d Scanner for David 3D Laserscanner

gdjump wrote:i have never ued 3D barcode scanner, is there any different between the 1D barcode scanner and 2D barcode scanner. so when can i used it, can i use it on the normal barcodes,

Hi, gdjump.

I don't think 3D barcode scanner can work with barcode reading so well. But have you ever tried 3D scanners to deal with scanning process other than barcodes?

Best regards,

Arron