LED "Eyes" ...

LED "Eyes" ...

Hi all.

I'm looking for info on how to install LED "eyes" into my Robobuilder's head. I did a search, but didn't find much.

I have the 5720T. I'm looking for what pins to connect to and if I need a couple of resistors to limit current to them.

Thanks!

I'm looking for info on how to install LED "eyes" into my Robobuilder's head. I did a search, but didn't find much.

I have the 5720T. I'm looking for what pins to connect to and if I need a couple of resistors to limit current to them.

Thanks!

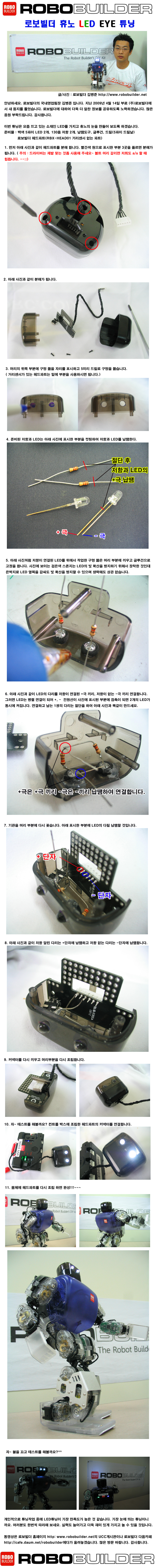

How's this (hopefully pictures are explanatory unless you know korean)

http://robosavvy.com/Builders/l3v3rz/20 ... 161555.jpg

http://robosavvy.com/Builders/l3v3rz/20 ... 161555.jpg

That's great l3vlrz!

I would also be interested in seeing how Pedro did his "Cylon" LED bar mod from an earlier thread.

I would also be interested in seeing how Pedro did his "Cylon" LED bar mod from an earlier thread.

PedroR wrote:here's a video of my homebrew head -

http://www.youtube.com/watch?v=GQqoZW8N6JQ

The sound is added on afterwards - until I can't work out how to generate it.

There are picture on Flikr as well. As you can see there's not much room to add you own circuits inside the head,

The circuit is based on a16F627 PIC chip and a 10 segment bar LED chip plus a few extra resistors. Very simple. I'm now working on providing control from the homebrew OS.

"She'll make point five past lightspeed. She may not look like much, but she's got it where it counts, kid. I've made a lot of special modifications myself."

Actually that was me.

This uses a PIC 16F627 chip to connect to the power (red and black wires you can see - yellow was a signal line I don't use any more). Then 10 of I/O lines are connected to one side of BAR LED. I common the other side of the LED pins together and via a resistor to earth. I also have an IO line connected to a piezo transducer, and two more connected to the TX/RX lines and via wcK cable into the RBC unit. This enables me to control which LED are on /off and sound/tone produced via the on board unit using Homebrew OS.

Hardware-wise it's all built on veroboard - total cost under £10. Although you do need a PIC programmer as well. Software its used SDCC C compiler - which is a bit clunky. For the future I'm think of adding a Analog servo to control the head of another PIC port and building a single board including the IR and PSD sensors, rather than having a separate board at the moment.

l3v3rz

This uses a PIC 16F627 chip to connect to the power (red and black wires you can see - yellow was a signal line I don't use any more). Then 10 of I/O lines are connected to one side of BAR LED. I common the other side of the LED pins together and via a resistor to earth. I also have an IO line connected to a piezo transducer, and two more connected to the TX/RX lines and via wcK cable into the RBC unit. This enables me to control which LED are on /off and sound/tone produced via the on board unit using Homebrew OS.

Hardware-wise it's all built on veroboard - total cost under £10. Although you do need a PIC programmer as well. Software its used SDCC C compiler - which is a bit clunky. For the future I'm think of adding a Analog servo to control the head of another PIC port and building a single board including the IR and PSD sensors, rather than having a separate board at the moment.

l3v3rz

oops! =)

Well good work again l3v3rz!

I really like that mod... very kewl!

I'm definitely going to give it a try when I get up the nerve to

start hacking up my shiny new robot! LOL

Well good work again l3v3rz!

I really like that mod... very kewl!

I'm definitely going to give it a try when I get up the nerve to

start hacking up my shiny new robot! LOL

"She'll make point five past lightspeed. She may not look like much, but she's got it where it counts, kid. I've made a lot of special modifications myself."

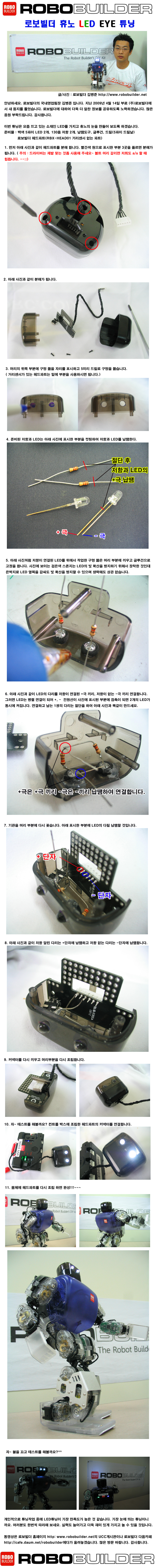

Check this out - they've improved the "head tuning"

Full link http://robobuilder.net/board/ucc/board_ ... itle_name=

For details and video

Full link http://robobuilder.net/board/ucc/board_ ... itle_name=

For details and video