by nunogato » Wed Oct 06, 2010 11:26 am

by nunogato » Wed Oct 06, 2010 11:26 am

by nunogato

by nunogato

Wed Oct 06, 2010 11:26 am

.jpg) Overview:

Overview:

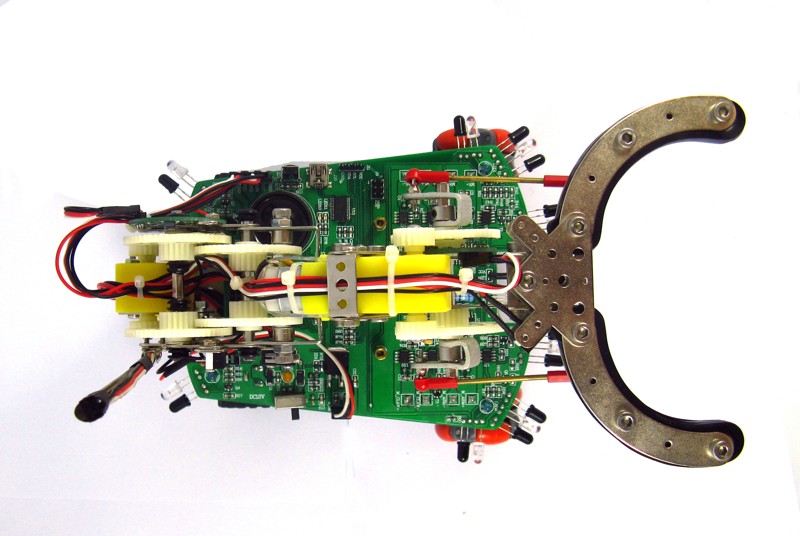

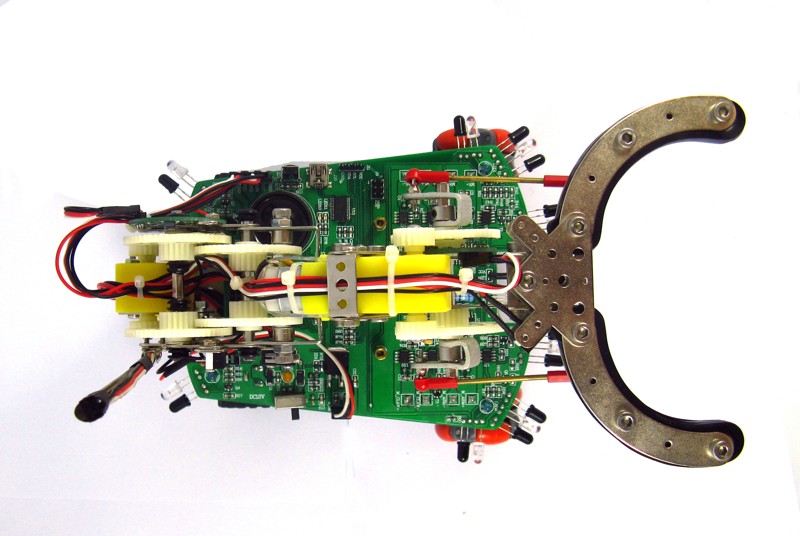

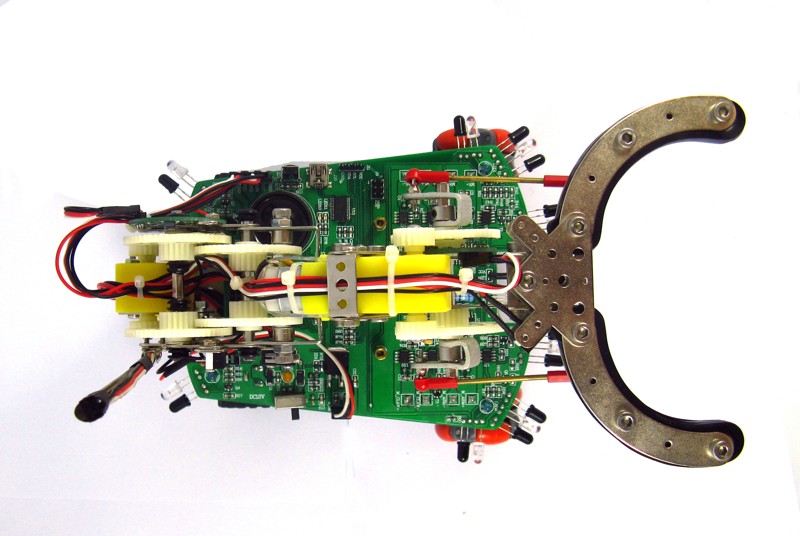

Mr. Tidy is an ideal experimental platform for those learning about robots. This robot was designed for students and hobbyist alike who want to learn about robots. Designed originally for sorting objects such as cups and cans according to colour size and weight, following a line and beacon navigation this robot has a lot to offer as an educational tool.

- Sorts objects by colour using it's RGB sensor

- Sorts objects by weight using current sensing of the arm lifting motor

- Sorts objects by size using the gripper encoder

Although a complete robot in itself, this platform has a lot of room for expansion through the use of additional sensors, wireless communications, LCD displays etc.

An I2C socket allows the easy addition of RTC (real time clock), memory expansion and other devices.

Video of the robot stacking cups according to colour can be seen here:

Processor:Mr. Tidy robot uses the

ATmega1280 CPU. This is an

Arduino / AVR compatible system.

16MHz ATmega1280 MCU has 128K of flash program memory, 4K EEPROM and 8K SRAM

The processor can be programmed via the USB interface with a standard USB cable (supplied) and the Arduino programming environment freely available from the Internet. More advanced users can program the robot via an ISP socket using AVR software also freely available from the Internet.

The robot has an aluminium chassis. The framework of the arm is nickel plated steel (Meccano compatible). Dual heavy duty gear trains and clutches make this robot hard to break.

The array of IR sensors surrounding the main boards serve not only for collision avoidance but also allow the robot to locate an object, judge it's size and align the gripper accurately with the object.

A RGB colour sensor on the front of the robot is used to determine the objects colour.

An IR receiver on an aerial at the back of the robot can be used to accept IR commands from a TV remote or for beacon navigation.

The robot is 4WD and uses double omni wheels at the front for smooth skid steering and to assist when aligning the gripper with an object to be picked up. Rubber tires at the rear ensure good traction on smooth surfaces. All 4 motors are driven by FET "H" bridges with current sensing and optical pulse encoders.

The robot requires 6x AA (UM3) NiMh rechargeable batteries. As the robot is designed with the ability to recharge it's own batteries (when using a docking station) the power switch does not turn the robot off when recharging. The sample software currently provided measures the battery voltage, detects when charging is occurring and switches to a stationary low power mode that can only be exited by resetting the processor.

Drive method:- Skid steer assisted by double omni-wheels at the front and rubber tyres at the rear.

Motors and encoders:- 4x DC motors, all motors driven by FET "H" bridge with current sensing and optical pulse encoders as shown in the photos below.

Sensors:- 8x IR analog sensors used for object detection, gripper alignment and obstacle avoidance. These sensors work best indoors, strong ambient IR will reduce their effective range.

- 1x 38KHz IR receiver for accepting remote commands or for navigation by IR beacons e.g. locating docking station.

- 1x RGB colour sensor.

I/O:- The processor has 70 I/O pins of which 42 are used by motors, encoders and sensors. The optional line follower PCB uses an aditional 5.

- Unused I/O pins are available via an expansion socket. These pins include analog inputs and PWM outputs.

Communications:- The ATmega1280 has 4x SUART's of which one is used by the USB/serial interface for program downloads, debugging etc.

- SUART's 2 and 3 are available on the expansion socket for uses such as wireless communications and serial LCD display.

- I2C pins plus Vcc and Gnd are available as a seperate socket on the mainboard.

Power:- 6x AA (UM3) NiMh rechargeable batteries supply power for the robot. The robot monitors their voltage and if provided with a suitable docking station (not currently available) can recharge it's own batteries without human assistance. The power switch does not disable the robot during recharging as the robot is capable of delta V charging. Current sample software provided recognises when charging is initiated and puts the robot into a low power mode which can only be exited by pressing the reset button. Once a docking station is available the sample software will be updated for delta V charging at which point the robot can self disengage and turn off if neccessary.

PCB testing and Sample Software:- The mainboard is first loaded with the Arduino Mega bootloader and tested in the factory using a diagnostic program (supplied online and/or on CD). This software includes all the basic functions (subroutines) neccessary to opperate the motors and sensors and may be usefull for customers writing their own software. The mainboard is then loaded with sample software for picking up and sorting objects according to colour. Additional features may be added to the sample software in the future.

Package content:- Quality aluminium chassis.

- Strong nickel plated steel framework for the arm.

- Heavy duty double gear trains for the arm and gripper.

- 2DOF arm with large steel gripper and silicone rubber grip pads.

- Skid steering assisted by double omni-wheels at the front.

- 128K of flash memory, 8K of SRAM and 4K of EEPROM.

- DC charging socket for battery trickle charge.

- Battery voltage monitoring.

- 4x FET "H" bridges with <span>current sensing</span>.

- 4x pulse encoders.

- 4x digital IR sensors for collision avoidance.

- 4x analog IR sensors for object detection and gripper alignment.

- 1x RGB colour sensor to determine object colour.

- 1x IR receiver for beacon navigation or receiving commands via TV remote.

- 1x socket for optional line following PCB or IR compound eye.

- 1x I²C socket.

- 1x expansion socket for access to unused analog, PWM, comms and digital I/O pins.

Inventor's Blog: The inventor of Mr. Tidy is Australian born alias named

Russell "OddBot" who has created many robots and works as resident robot inventor at Dagu.

Notes during creation of earlier prototypes of Mr. Tidy can be found

here.

.jpg) Overview:

Overview:

Mr. Tidy is an ideal experimental platform for those learning about robots. This robot was designed for students and hobbyist alike who want to learn about robots. Designed originally for sorting objects such as cups and cans according to colour size and weight, following a line and beacon navigation this robot has a lot to offer as an educational tool.

- Sorts objects by colour using it's RGB sensor

- Sorts objects by weight using current sensing of the arm lifting motor

- Sorts objects by size using the gripper encoder

Although a complete robot in itself, this platform has a lot of room for expansion through the use of additional sensors, wireless communications, LCD displays etc.

An I2C socket allows the easy addition of RTC (real time clock), memory expansion and other devices.

Video of the robot stacking cups according to colour can be seen here:

Processor:Mr. Tidy robot uses the

ATmega1280 CPU. This is an

Arduino / AVR compatible system.

16MHz ATmega1280 MCU has 128K of flash program memory, 4K EEPROM and 8K SRAM

The processor can be programmed via the USB interface with a standard USB cable (supplied) and the Arduino programming environment freely available from the Internet. More advanced users can program the robot via an ISP socket using AVR software also freely available from the Internet.

The robot has an aluminium chassis. The framework of the arm is nickel plated steel (Meccano compatible). Dual heavy duty gear trains and clutches make this robot hard to break.

The array of IR sensors surrounding the main boards serve not only for collision avoidance but also allow the robot to locate an object, judge it's size and align the gripper accurately with the object.

A RGB colour sensor on the front of the robot is used to determine the objects colour.

An IR receiver on an aerial at the back of the robot can be used to accept IR commands from a TV remote or for beacon navigation.

The robot is 4WD and uses double omni wheels at the front for smooth skid steering and to assist when aligning the gripper with an object to be picked up. Rubber tires at the rear ensure good traction on smooth surfaces. All 4 motors are driven by FET "H" bridges with current sensing and optical pulse encoders.

The robot requires 6x AA (UM3) NiMh rechargeable batteries. As the robot is designed with the ability to recharge it's own batteries (when using a docking station) the power switch does not turn the robot off when recharging. The sample software currently provided measures the battery voltage, detects when charging is occurring and switches to a stationary low power mode that can only be exited by resetting the processor.

Drive method:- Skid steer assisted by double omni-wheels at the front and rubber tyres at the rear.

Motors and encoders:- 4x DC motors, all motors driven by FET "H" bridge with current sensing and optical pulse encoders as shown in the photos below.

Sensors:- 8x IR analog sensors used for object detection, gripper alignment and obstacle avoidance. These sensors work best indoors, strong ambient IR will reduce their effective range.

- 1x 38KHz IR receiver for accepting remote commands or for navigation by IR beacons e.g. locating docking station.

- 1x RGB colour sensor.

I/O:- The processor has 70 I/O pins of which 42 are used by motors, encoders and sensors. The optional line follower PCB uses an aditional 5.

- Unused I/O pins are available via an expansion socket. These pins include analog inputs and PWM outputs.

Communications:- The ATmega1280 has 4x SUART's of which one is used by the USB/serial interface for program downloads, debugging etc.

- SUART's 2 and 3 are available on the expansion socket for uses such as wireless communications and serial LCD display.

- I2C pins plus Vcc and Gnd are available as a seperate socket on the mainboard.

Power:- 6x AA (UM3) NiMh rechargeable batteries supply power for the robot. The robot monitors their voltage and if provided with a suitable docking station (not currently available) can recharge it's own batteries without human assistance. The power switch does not disable the robot during recharging as the robot is capable of delta V charging. Current sample software provided recognises when charging is initiated and puts the robot into a low power mode which can only be exited by pressing the reset button. Once a docking station is available the sample software will be updated for delta V charging at which point the robot can self disengage and turn off if neccessary.

PCB testing and Sample Software:- The mainboard is first loaded with the Arduino Mega bootloader and tested in the factory using a diagnostic program (supplied online and/or on CD). This software includes all the basic functions (subroutines) neccessary to opperate the motors and sensors and may be usefull for customers writing their own software. The mainboard is then loaded with sample software for picking up and sorting objects according to colour. Additional features may be added to the sample software in the future.

Package content:- Quality aluminium chassis.

- Strong nickel plated steel framework for the arm.

- Heavy duty double gear trains for the arm and gripper.

- 2DOF arm with large steel gripper and silicone rubber grip pads.

- Skid steering assisted by double omni-wheels at the front.

- 128K of flash memory, 8K of SRAM and 4K of EEPROM.

- DC charging socket for battery trickle charge.

- Battery voltage monitoring.

- 4x FET "H" bridges with <span>current sensing</span>.

- 4x pulse encoders.

- 4x digital IR sensors for collision avoidance.

- 4x analog IR sensors for object detection and gripper alignment.

- 1x RGB colour sensor to determine object colour.

- 1x IR receiver for beacon navigation or receiving commands via TV remote.

- 1x socket for optional line following PCB or IR compound eye.

- 1x I²C socket.

- 1x expansion socket for access to unused analog, PWM, comms and digital I/O pins.

Inventor's Blog: The inventor of Mr. Tidy is Australian born alias named

Russell "OddBot" who has created many robots and works as resident robot inventor at Dagu.

Notes during creation of earlier prototypes of Mr. Tidy can be found

here.

.jpg)