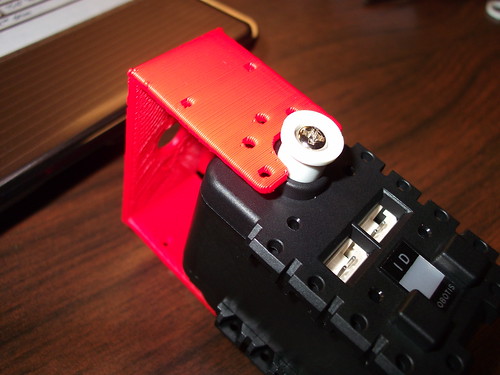

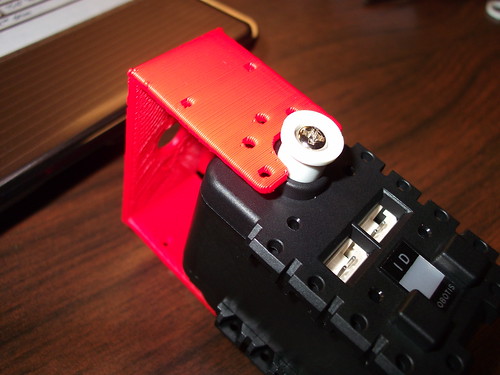

First Attempt to print out DARwIn-OP brackets!

billyzelsnack wrote:Looks great.

I was inspired to print one out myself. Once again I am seeing the same problem with printing brackets. The side wall strength is pretty poor because of layer delamination. I really want to figure out why. Yeah my print has other various issues, but right now I am more concerned about part strength. Any ideas on why your part is so much stronger than mine?

http://www.youtube.com/watch?v=e0YZ_9ERO7s

BTW. How wide did your bracket sides end up printing out? The model is 2mm and mine ends up at 2.32mm.

Without seeing your profile settings I can't really say. With any thin-walled object you want to take -Extra Shells- under Fill to all zeros. I also have an infill of 1 or 100%. It could be the layer height and I am putting out a bit more plastic then I should be. So to confuse things even more the filament really isn't complety uniform so with this version of rep g you have to fudge it a litte and play with the filament size up or down, I can't seem to remember which way, to adjust plastic output. I'm not doing justice to how much math is happening behind the scenes with respect to amount of plastic being extruded/entering/exiting the nozzle. I don't fully understand it but I know it works. I have to also track down a few vibrations somewhere because any play anywhere transfers to your model output.

It was set to fill 100% and I never use extra shells. 0.4mm layer height.

I do have my cooling set to slow down with a minimum layer time of 20 seconds. This could be a problem for the top of the print, but the lower side of part is still too weak.

The only other thing I can think of is that my print temp swings have been getting worse over time. +-10 degrees! Still, I keep it high enough so the low side of the swing is 220. Maybe the variance causes substantial weakness? I guess I should look into tweaking that.

I do have my cooling set to slow down with a minimum layer time of 20 seconds. This could be a problem for the top of the print, but the lower side of part is still too weak.

The only other thing I can think of is that my print temp swings have been getting worse over time. +-10 degrees! Still, I keep it high enough so the low side of the swing is 220. Maybe the variance causes substantial weakness? I guess I should look into tweaking that.

Looks like we just hacked the brackets! Hooyah!

http://mike-ibioloid.blogspot.com/2011/ ... in-op.html

http://mike-ibioloid.blogspot.com/2011/ ... in-op.html