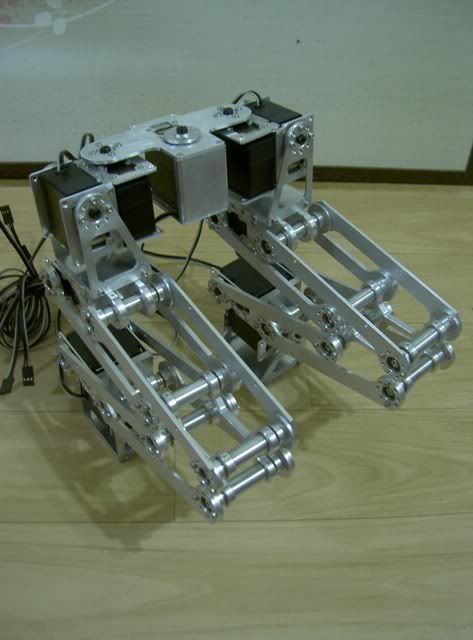

Parallel Leg Mechanism Design Discussion

Tyberius,

Work on my parallel leg design is moving very slowly. I still have a number of parts to make. I am very impressed with your latest design.

While doing a little testing it occurred to me that as the leg part is driven from both ends there is no real need for the parallel structure. The servos, by being in master/slave configuration, effectively produce the same movement as the introduction of the parallel element. Have you considered this in your design?

Peter

Work on my parallel leg design is moving very slowly. I still have a number of parts to make. I am very impressed with your latest design.

While doing a little testing it occurred to me that as the leg part is driven from both ends there is no real need for the parallel structure. The servos, by being in master/slave configuration, effectively produce the same movement as the introduction of the parallel element. Have you considered this in your design?

Peter

Ausrobo wrote:Tyberius,

Work on my parallel leg design is moving very slowly. I still have a number of parts to make. I am very impressed with your latest design.

While doing a little testing it occurred to me that as the leg part is driven from both ends there is no real need for the parallel structure. The servos, by being in master/slave configuration, effectively produce the same movement as the introduction of the parallel element. Have you considered this in your design?

Peter

You don't have the option of offsetting the two paired servos slightly to reduce/eliminate backlash however, nor the physical structure to support that.

Apologies for digging up an oldish thread... but I'm just now getting (back) into the hobby, and have stumbled across this very helpful info.

I discovered parallel linkage legs in Hitec, which did very well in this year's Robo-One contest with only 11 servos. That rocks. I'd like to do the same thing using RoboBuilder servos (mainly because I already have a lot of them — though I'm tempted to try the new UpTech servos too, because they're slightly stronger and cheaper).

So I'm starting the slow process of learning to design and fabricate my own brackets. Most of this is straightforward, if not easy for a software geek like me. But one thing I still don't know:

What are you guys using for the bearings in these things?

Seems to me that one leg has about 16 of these, and they need to be fairly small... and they're load-bearing, too. Is this just some combination of standard screws and washers, or are you using something more sophisticated?

Thanks,

- Joe

I discovered parallel linkage legs in Hitec, which did very well in this year's Robo-One contest with only 11 servos. That rocks. I'd like to do the same thing using RoboBuilder servos (mainly because I already have a lot of them — though I'm tempted to try the new UpTech servos too, because they're slightly stronger and cheaper).

So I'm starting the slow process of learning to design and fabricate my own brackets. Most of this is straightforward, if not easy for a software geek like me. But one thing I still don't know:

What are you guys using for the bearings in these things?

Seems to me that one leg has about 16 of these, and they need to be fairly small... and they're load-bearing, too. Is this just some combination of standard screws and washers, or are you using something more sophisticated?

Thanks,

- Joe